Airports around the world are facing a tall order: reach net-zero carbon, some by 2050 and others as soon as 2030. While most discussions on decarbonization focus on operational carbon from day-to-day energy use, a significant piece of the puzzle is often overlooked: embodied carbon. Embodied carbon includes all emissions from producing, transporting, and assembling building materials.

For large, complex structures like airport terminals and air traffic control towers, structural systems alone can account for 50–80% of a building’s embodied carbon. That makes structural optimization a high-impact strategy for reducing embodied carbon, and one powerful way to achieve it is through wind loading assessments in a wind tunnel.

Operational vs. Embodied Carbon at Airports

Operational carbon has long been a focus of green building efforts, including for airports. Operational carbon includes the carbon emissions generated from operating an airport, such as heating, cooling, lighting, and other building operations. But as grids decarbonize and energy efficiency improves, embodied carbon is taking a larger share of lifetime carbon emissions. For airports, carbon intensive materials like concrete and steel are major targets for reduction.

Embodied Carbon & Airport Building Materials

A Life Cycle Assessment (LCA) is a method for measuring the total environmental impact of a building or product from raw material extraction through construction, use, and end-of-life. LCAs reveal where the biggest impacts occur, guiding smarter material choices. For example:

- Concrete emissions stem mainly from cement content—reducing cement, using supplementary materials like fly ash or slag, and choosing mixes with longer cure times can cut emissions by 10% or more.

- Steel, because of the smelting process, traditionally requires large amounts of energy and fossil fuels. Steel made via electric arc furnaces from recycled content can have less than half the emissions of conventional production.

While making smarter material choices can reduce the carbon footprint, what if we could reduce the total material need at the outset?

The Link Between Wind Loads and Embodied Carbon

Here’s where wind engineering comes in: a terminal or air traffic control tower built to withstand high wind loads requires heavier, more material-intensive structures.

Most building codes use conservative wind load estimates based on generic building shapes and open terrain. But airports are anything but generic. Their terminals often feature sweeping curves, large canopies, and complex roof geometries that interact with wind in unique ways.

Overestimating wind loads leads to heavier structures, more concrete and steel, and therefore higher embodied carbon. It also drives up material costs unnecessarily, increasing the cost of the overall project.

By conducting site-specific wind assessments, airports can reduce wind load estimates leading to lighter structures, lower emissions, and significant cost savings.

In our experience conducting these site-specific wind assessments for airports around the world, we have seen that 9 out of 10 projects see reduced loads compared to code, often by 15–25% with a detailed wind assessment.

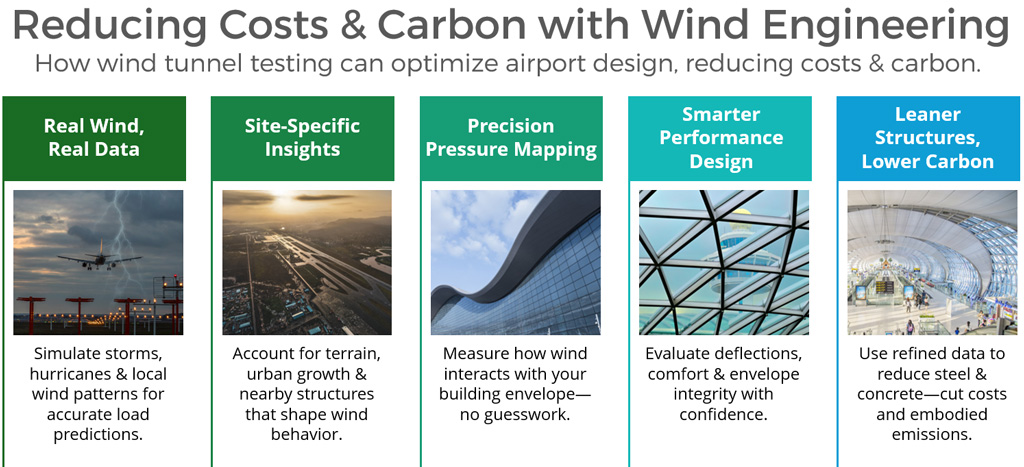

A detailed wind assessment based on wind tunnel testing provides a more accurate picture so that the design teams can:

- Understand the wind climate (including storms, hurricanes, thunderstorms)

- Account for site exposure (urban growth around airports changes wind profiles)

- Measure pressures across the building envelope

- Evaluate performance criteria (structural deflections, comfort, envelope integrity)

- Optimize design of the structural systems and envelope to reduce the quantities of steel and concrete

How Wind Tunnel Testing Can Reduce Carbon & Cost in Airport Design

A detailed wind assessment using wind tunnel testing goes far beyond code-based estimates. It provides a nuanced, site-specific understanding of how wind interacts with the unique geometry and surroundings of an airport. This precision empowers design teams to make informed decisions that reduce material use, improve performance, and lower embodied carbon. Here’s how:

1. Understanding the Wind Climate

Wind tunnel testing incorporates regional meteorological data to simulate realistic wind conditions, including extreme events like thunderstorms, hurricanes, and seasonal storms. This allows engineers to:

- Identify prevailing wind directions and intensities.

- Model rare but critical wind events that could impact structural integrity.

- Design for resilience without overbuilding, ensuring safety while minimizing unnecessary material use.

2. Accounting for Site Exposure

Airports are dynamic environments. Urban development around them—new buildings, infrastructure, and vegetation—can significantly alter wind patterns over time. Wind tunnel testing accounts for:

- Current and future site exposure, including terrain roughness and obstructions.

- The shielding or channeling effects of nearby structures.

- How wind accelerates or decelerates across the site, influencing localized pressures.

This helps avoid conservative assumptions and ensures the design reflects actual conditions.

3. Measuring Pressures Across the Building Envelope

Unlike generic code-based models, wind tunnel testing provides high-resolution data on pressure distribution across the building envelope. This includes:

- Localized suction and uplift forces on roofs and façades.

- Peak pressures on corners, edges, and overhangs.

- Realistic load cases for complex geometries like curved roofs and cantilevered canopies.

This data enables precise structural design, reducing the need for over-reinforcement and excess material.

4. Evaluating Performance Criteria

Wind tunnel results feed directly into performance evaluations, helping teams assess:

- Structural deflections: Ensuring that movement under wind loads stays within acceptable limits.

- Occupant comfort: Minimizing wind-induced vibrations and noise in public areas.

- Envelope integrity: Preventing wind-driven rain infiltration and façade damage.

These insights support smarter decisions about materials, connections, and detailing.

5. Optimizing Structural Systems and Envelope Design

With accurate wind load data, engineers can confidently reduce the size and quantity of structural elements. This leads to:

- Less steel and concrete: Lower embodied carbon and material costs.

- Slimmer profiles: More architectural freedom and better spatial efficiency.

- Targeted reinforcement: Only where it’s needed, not everywhere.

In many cases, this optimization results in 15–25% reductions in wind loads compared to code, translating to substantial savings in both carbon and cost.

Case Study: How RWDI’s Wind Engineering Consulting Helped Create a Smarter, Greener Airport Structure for Mexico City International Airport

In one high-profile project, we worked on the striking, grid-shell-roofed Mexico City International Airport, designed by Foster + Partners. Code-based preliminary designs assumed wind pressures of around 1.0–1.5 kPa on key structural elements. Wind tunnel testing revealed actual loads were 30–35% lower than code.

The result? Structural engineers were able to redesign the roof and enclosure to use less concrete and steel, reducing 130 million kilograms of CO₂ equivalent—and saving $3–5 million in material costs.

Though the project was ultimately halted for unrelated political reasons, it remains a powerful example of how early-stage wind studies can deliver both environmental and economic wins.

The Takeaway for Airport Projects

Airports are complex, high-stakes infrastructure projects. To hit net-zero goals and reduce capital costs, airport design teams should:

- Address embodied carbon early—set reduction targets at the concept stage.

- Use detailed wind assessments to inform structural design, especially for unique or complex forms.

- Compare materials with environmental product declarations (EPDs) to make lower-carbon choices.

- Optimize spans and overhangs without sacrificing the architectural vision.

By integrating wind engineering with carbon-conscious material selection, airports can reduce both costs and climate impact—ensuring these critical transportation hubs are built for a sustainable future.